In the industry of metal finishings, rack plating is one of the most common processes when plating small pieces. Jewelry items such as earrings and other small pieces or parts are plated using a rack, to ensure that they are plated uniformly from every angle. Also, attaching them to a rack makes it easier to immerse them in plating solutions without them touching each other or being damaged in the process.

All Kinds of Products Require a Variety of Racks

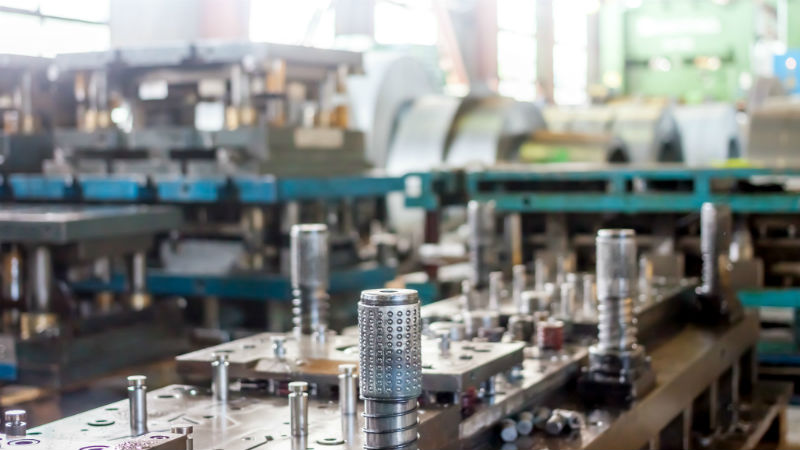

Before any piece or part can be plated with silver, gold, copper, nickel, zinc or other special metal finish, it goes through several steps using the rack plating equipment. Specially coated plating racks are used, and the items are fastened to them in different ways depending on the item itself. Some pieces or parts are screwed to the rack. Others are hung using a special spring or wires. Every plating job is unique and various rack designs exist to meet the demands of a range of industries.

Plating Manually or by Machine

Many metal finishing companies that specialize in various forms of plating have small stations set up to plate on a rack manually. Their specialists dip each rack by hand, rinse the rack and take it manually through the entire plating process. Other companies are handling bigger pieces use very large stations and oversized tanks for high volume plating demands. No matter what product is being plated, metal finishers often have custom racks to handle specific customer needs. In both cases, plating takes time, patience and care.

Advantages of Rack Plating

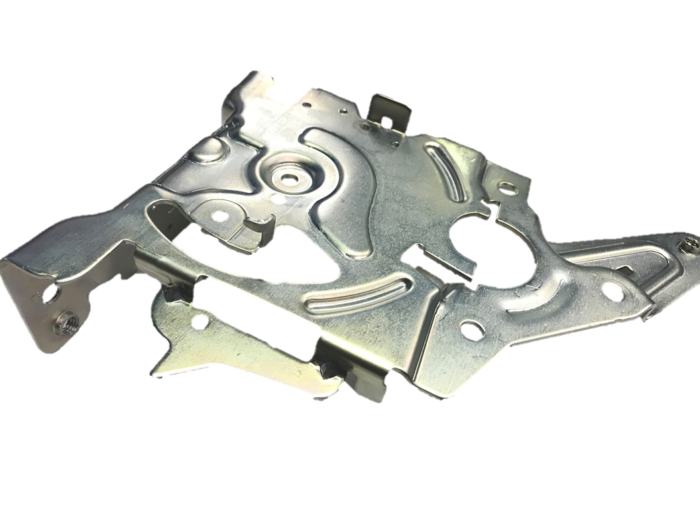

Rack plating is ideal for fragile pieces or small, intricate items. It is also used for larger, complex pieces that may have an awkward shape or size. There are many advantages to plating on a rack:

* The rack remains still during the plating process, allowing the coating to be deposited on every side, top, and bottom

* The rack itself is immersed in various solutions and coatings, and the pieces are fastened to the rack to prevent loss

* If a piece is intricate, every nook and cranny is plated

* A higher quality finish is achieved with rack plating vs. other plating processes such as barrel plating.

* Smaller pieces are easier to manage, and quality control can inspect the finished product with greater ease when pieces are hung from a rack in front of inspectors.

Popular Finishes

Jewelry is generally coated with silver and gold finishes, while hinges, door handles and other hardware are coated in chrome or nickel. These are all products that are typically plated using a rack.

When it comes to quality plating and metal finishing, you can rely on the experts at Dekalb Metal Finishing to deliver on their promise of quality workmanship and service of the highest caliber. To find out more about their rack plating capabilities, visit www.dekalbmetal.com.