When it comes to protecting metal parts from rust and corrosion, choosing the right plating method is crucial. Zinc nickel plating has become a popular choice for both industrial and commercial applications, given its superior performance compared to other types of plating.

In this blog post, we will delve into the advantages of using zinc nickel plating services for your products.

Outstanding Corrosion Resistance

One benefit of zinc nickel plating properties is the outstanding corrosion resistance it provides. Corrosion can quickly weaken or damage metal parts, leading to unwanted downtime, replacements, or repairs.

The zinc nickel coating acts as a barrier between the metal and the environment, reducing the potential for rust and oxidation. The plating provides up to 1,000 hours or more of salt spray resistance, making it ideal for lasting durability even in the harshest environments.

Enhanced Wear Resistance

Zinc-nickel plated surfaces also offer high wear resistance characteristics. Products exposed to wear and friction can have their lifespan significantly reduced without proper plating. Zinc-nickel plating extends the service life of such products, thanks to its anti-abrasion properties. The plating layer is also harder than traditional zinc plating, making it wear-resistant and less prone to chip or peel.

Wide Range of Applications

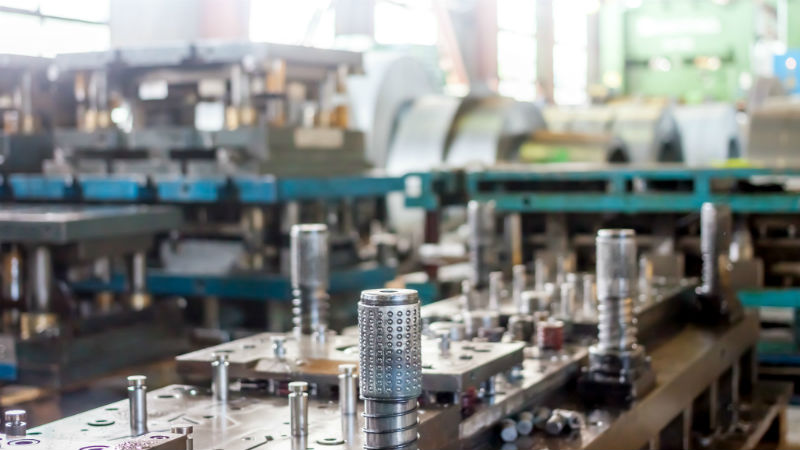

High-Quality Zinc nickel plating services are suitable for various applications ranging from automotive and aerospace to marine and electronics. Its superior performance is also ideal for military and industrial applications such as pipelines and valves, where high-performance coatings are necessary. Zinc-nickel plating is also compatible with different types of base metals, making it a versatile solution for many products.

Efficiency in Processing

The manufacturing process for zinc-nickel plating is efficient and often more cost-effective than other coating types. It can be applied by electroplating, electroless, or mechanical plating methods, depending on factors such as the size, shape, and complexity of the parts. The plating process also requires less maintenance, resulting in minimal production downtime and cost savings.